PR-Series

Precise complete machining

Precise complete machining

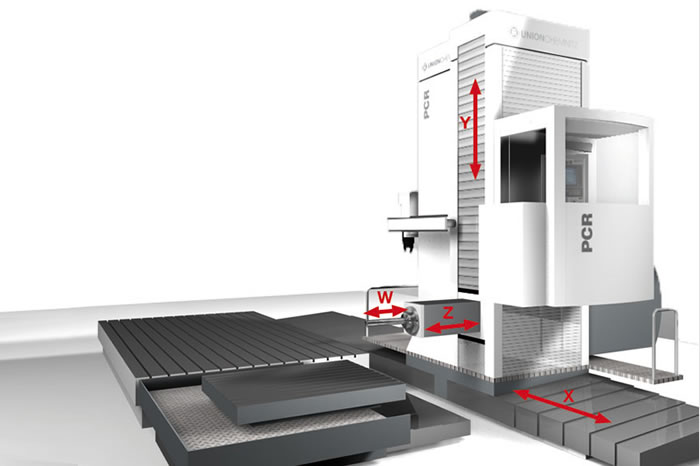

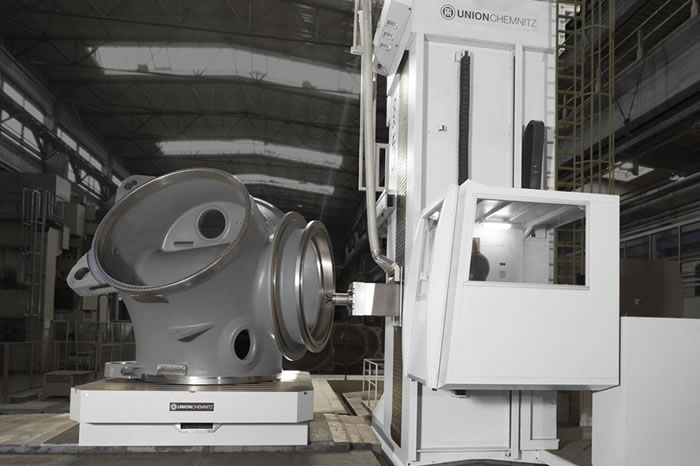

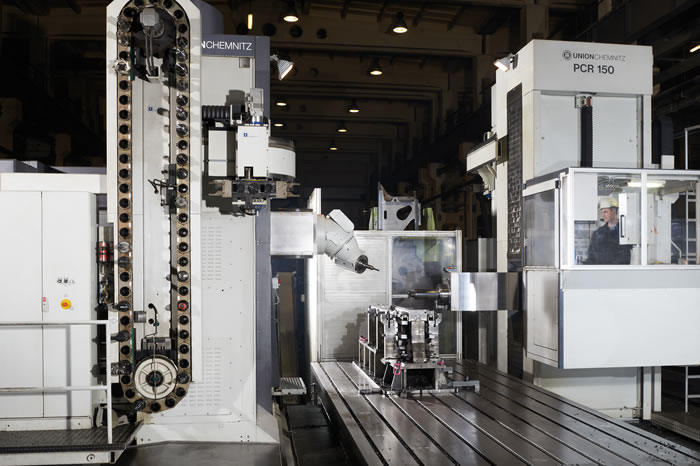

The horizontal boring mills of the PR-series with a floor plate and ram are the ideal machine tools for the machining of large workpieces. Besides stable heavy roughing, they also allow highly precise finishing and five-side machining of workpieces up to 250 t.

Efficiently applied flexibility

The integration of floor plates, variable clamping tables and trunnion devices as well as efficient and automatic changing of different additional milling units or heavy tools via a pick-up-station guarantees the efficient machining of the workpieces.

Classification

- P Floor type

- C With automatic tool changer

- R With ram

Type range

- I, II, III

Boring spindle diameters available

- 130, 150, 162, 180, 200, 262 mm

The advantages of the PR-series at a glance

- Promotes both rough machining and high-precision super-finishing

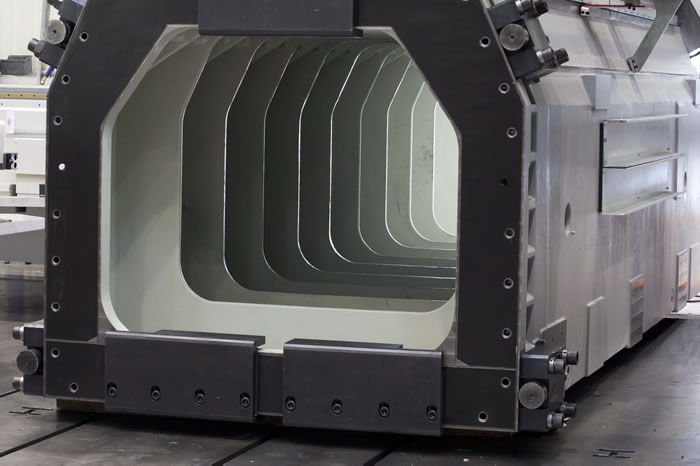

- Double hydrostatic guideways that completely enclose the ram

- Dynamically controlled hydrostatic systems

- Extremely rigid and heavily ribbed column

- Compensation of spindle and ram droop and column tilt

- Length compensation of boring spindle and ram (option)

- Temperature-controlled hydrostatic oil for thermal stability of the machine

The PR 130 / PR 150 / PR 160 / PR 180 design

The robust machine bed with a double pinion drive with zero backlash within the gear rack as well as the strongly ribbed column result in extreme stiffness. Optionally, the guideways are designed either with regulated hydrostatics or preloaded linear-compact roller guides.

Moreover, various features provide precision for all applications: hydrostatic guides, a triple ram sag compensation, a double precision spindle bearing with permanent lubrication and a thermic monitoring of the spindle bearing in the ram.

The PR 200 / PR 260 design

The cast beds of the PR 200 and PR 260 are strongly ribbed and promote vibration damping, with guideways that are generously dimensioned. Water-cooled AC motors provide a sufficient driving power of the boring spindle and high feed forces in all axes.

X-, Y- and Z-axes are hydrostatic, so that even during the heaviest roughing operations the highest precision is achieved without friction or wear. The ram is hydrostatically guided as well, and manufactured with a spindle bearing, using a preloaded high-precision spindle and a cylinder roller bearing.

Options

Numerous options are available to perfectly adapt the machines of the PR-series to their respective fields of application:

Automatic tool changer

The tool magazines can accommodate up to 200 tools. The tool change can be efficiently carried out either horizontally or vertically.

Automatic accessory change from the pick-up station

A comprehensive range of milling heads, NC facing heads, support bearings, spindle extensions and special tools can be changed fully automatically for extra efficiency.

Process monitoring

The optimization of the machining processes results from active tool monitoring and automatic tool measurement, torque and collision monitoring as well as an operating data acquisition system and remote diagnostics using teleservice.

CNC-controls

Four variants are available: Siemens 840 D sl, Heidenhain iTNC 530, Heidenhain TNC 640 and Fanuc 31iB.

Complete solutions

The PR-series is flexibly applicable, due to rotary and traversing tables allowing up to 250 t, tilting tables with a positional rotary axis of 0°-90° as well as sine tables and high-speed tables, including a broad spectrum of milling heads.

Comprehensive range of equipment

You can choose from our broad spectrum of aggregates as well as rotary, traversing and tilting tables.

| Technical data | PR I | PR II | PR II S | PR III | |

| Boring spindle | |||||

| Diameter | mm | 130 / 150 | 130 - 200 | 162 - 200 | 180 - 262 |

| Drive power, max. | kW | 63 | 91 | 97 | 128 |

| Torque, max. | Nm | 3,100 | 7,094 | 7,534 | 19,847 |

| Speed, max. | min-1 | 4,400 | 4,000 | 3,000 | 2,200 |

| Traverses | |||||

| X-axis | mm | 4,000 | 4,000 | 4,000 | 4,000 |

| Extension in steps of | mm | 1,000 | 1,000 | 1,000 | 1,000 |

| Y-axis | mm | 2,000 | 2,500 | 2,500 | 3,000 |

| Extension in steps of 500 mm up to max. | mm | 4,500 | 6,500 | 6,500 | 10,000 |

| Z-axis | mm | 1,100 | 1,500 | 2,000 | 2,000 |

| W-axis | mm | 750 | 1,000 | 1,400 | 1,500 |

| Feed / Rapid traverses | |||||

| Feed range of all axes | mm/min | 10,000 | 10,000 | 10,000 | 8,000 |

| Rapid traverse of the linear axes, max. | mm/min | 32,000 | 28,000 | 25,000 | 20,000 |

| Feed force, max. | N | 20,000 | 40,000 | 40,000 | 60,000 |

| Technical data | PR I | |

| Boring spindle | ||

| Diameter | mm | 130 / 150 |

| Drive power, max. | kW | 63 |

| Torque, max. | Nm | 3,100 |

| Speed, max. | min-1 | 4,400 |

| Traverses | ||

| X-axis | mm | 4,000 |

| Extension in steps of | mm | 1,000 |

| Y-axis | mm | 2,000 |

| Extension in steps of 500 mm up to max. | mm | 4,500 |

| Z-axis | mm | 1,100 |

| W-axis | mm | 750 |

| Feed / Rapid traverses | ||

| Feed range of all axes | mm/min | 10,000 |

| Rapid traverse of the linear axes, max. | mm/min | 32,000 |

| Feed force, max. | N | 20,000 |

| Technical data | PR II | |

| Boring spindle | ||

| Diameter | mm | 130 - 200 |

| Drive power, max. | kW | 91 |

| Torque, max. | Nm | 7,094 |

| Speed, max. | min-1 | 4,000 |

| Traverses | ||

| X-axis | mm | 4,000 |

| Extension in steps of | mm | 1,000 |

| Y-axis | mm | 2,500 |

| Extension in steps of 500 mm up to max. | mm | 6,500 |

| Z-axis | mm | 1,500 |

| W-axis | mm | 1,000 |

| Feed / Rapid traverses | ||

| Feed range of all axes | mm/min | 10,000 |

| Rapid traverse of the linear axes, max. | mm/min | 28,000 |

| Feed force, max. | N | 40,000 |

| Technical data | PR II S | |

| Boring spindle | ||

| Diameter | mm | 162 - 200 |

| Drive power, max. | kW | 97 |

| Torque, max. | Nm | 7,534 |

| Speed, max. | min-1 | 3,000 |

| Traverses | ||

| X-axis | mm | 4,000 |

| Extension in steps of | mm | 1,000 |

| Y-axis | mm | 2,500 |

| Extension in steps of 500 mm up to max. | mm | 6,500 |

| Z-axis | mm | 2,000 |

| W-axis | mm | 1,400 |

| Feed / Rapid traverses | ||

| Feed range of all axes | mm/min | 10,000 |

| Rapid traverse of the linear axes, max. | mm/min | 25,000 |

| Feed force, max. | N | 40,000 |

| Technical data | PR III | |

| Boring spindle | ||

| Diameter | mm | 180 - 262 |

| Drive power, max. | kW | 128 |

| Torque, max. | Nm | 19,847 |

| Speed, max. | min-1 | 2,200 |

| Traverses | ||

| X-axis | mm | 4,000 |

| Extension in steps of | mm | 1,000 |

| Y-axis | mm | 3,000 |

| Extension in steps of 500 mm up to max. | mm | 10,000 |

| Z-axis | mm | 2,000 |

| W-axis | mm | 1,500 |

| Feed / Rapid traverses | ||

| Feed range of all axes | mm/min | 8,000 |

| Rapid traverse of the linear axes, max. | mm/min | 20,000 |

| Feed force, max. | N | 60,000 |

- P Floor type

- C With automatic tool changer

- R With ram

Product film